Check Media

This printer supports different media depending on the model.

Check the model name of your printer, referring to Check Model.

Then, check the supported media and their specifications and prepare the appropriate media.

You need to configure printer settings according to the media you use. For details, refer to Media Settings.

Media (label paper type)

The following media are available depending on the printer model.

| Available in the standard model | |||

| Unavailable in the LBL model | Available in the LBL model | ||

|

|

|

|

| Linerless label Label paper without liner or backing sheet and with glue sprayed on the back side. Cut to an optional length when using it. |

Continuous label Linered label paper. Cut to an optional length when using it. |

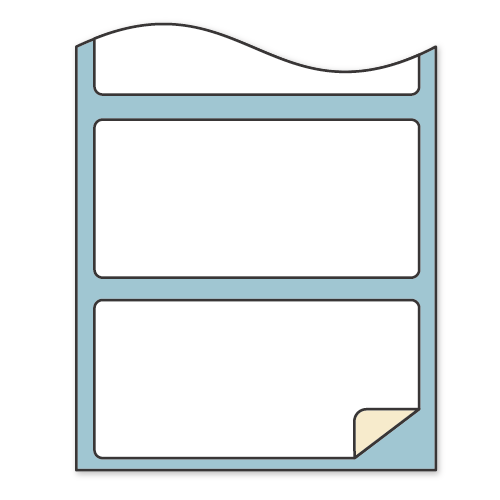

Die cut label Linered label paper. This has been cut to a specific size in advance. |

Receipt paper Heat-sensitive receipt paper without glue or liner. |

Paper roll specifications

Use paper rolls that comply to the specifications. Applicable specifications vary depending on the paper types.

Linerless label

| Paper width [W1] | 40 mm to 58 mm |

|---|---|

| Maximum roll diameter [D] | φ102 mm |

| Paper thickness | 68 μm to 93 μm |

| Color surface | Roll exterior |

| Termination process |

Continuous label

| Liner width [W1] | 25 mm to 60 mm |

|---|---|

| Maximum roll diameter [D] | φ102 mm |

| Paper thickness | 154 μm or less (total thickness) |

| Color surface | Roll exterior |

| Termination process |

Die cut label

| Liner width [W1] | 25 mm to 60 mm |

|---|---|

| Maximum roll diameter [D] | φ102 mm |

| Paper thickness | 154 μm or less (total thickness) |

| Color surface | Roll exterior |

| Termination process |

Receipt paper

| Paper width [W1] | 58 mm |

|---|---|

| Maximum roll diameter [D] | φ102 mm |

| Paper thickness | 49 μm to 150 μm |

| Color surface | Roll exterior |

| Termination process |

Die cut label

| Liner width [W1] | 25 mm to 60 mm |

|---|---|

| Maximum roll diameter [D] | φ102 mm |

| Paper thickness | 154 μm or less (total thickness) |

| Color surface | Roll exterior |

| Termination process |

Receipt paper

| Paper width [W1] | 58 mm |

|---|---|

| Maximum roll diameter [D] | φ102 mm |

| Paper thickness | 49 μm to 150 μm |

| Color surface | Roll exterior |

| Termination process |

Refer to here for consumable parts.

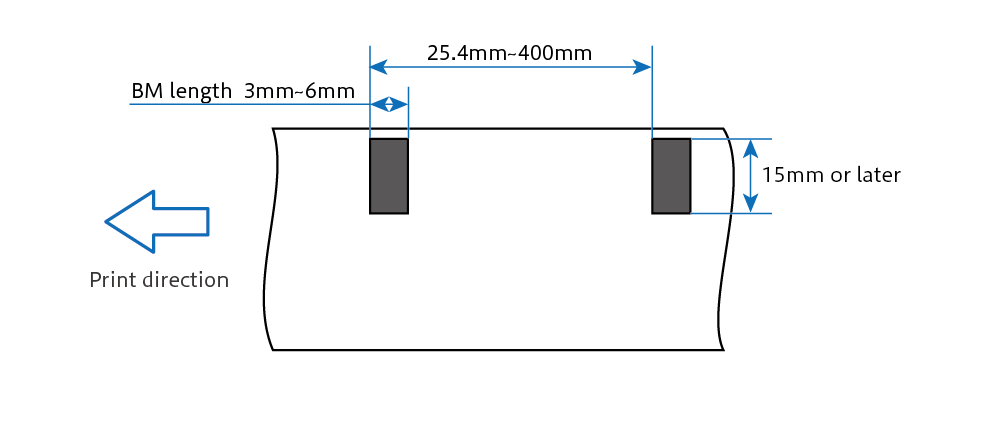

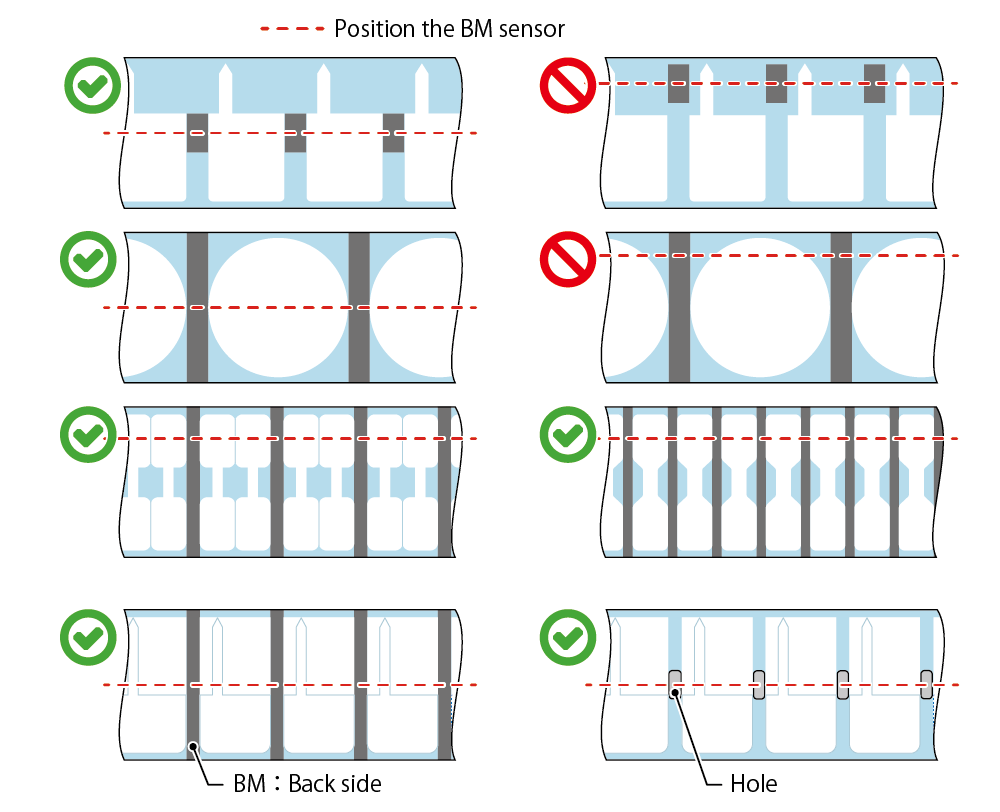

Available black mark paper specifications

- If you use black mark paper, be sure to adjust the sensor position so that the BM sensor overlaps the black mark. For detailed guidance, use Media Settings in Star Quick Setup Utility.

- If you use pre-printed paper, do not perform pre-printing within the area where the BM sensor passes on the back side of the paper. Be sure to fully verify operation beforehand.

Part Names and Functions > Inside of main unit  PE/BM Sensor

PE/BM Sensor

An example of using specially-shaped die cut label paper

When using the BM sensor

Make sure to use paper whose liner cannot be seen with no gap between the label paper and the black mark.

When the black mark detection is "Enabled", if a liner-only part passes the black mark sensor, printing may be stopped as it is determined to have no paper, or paper may not be cut at the correct position.

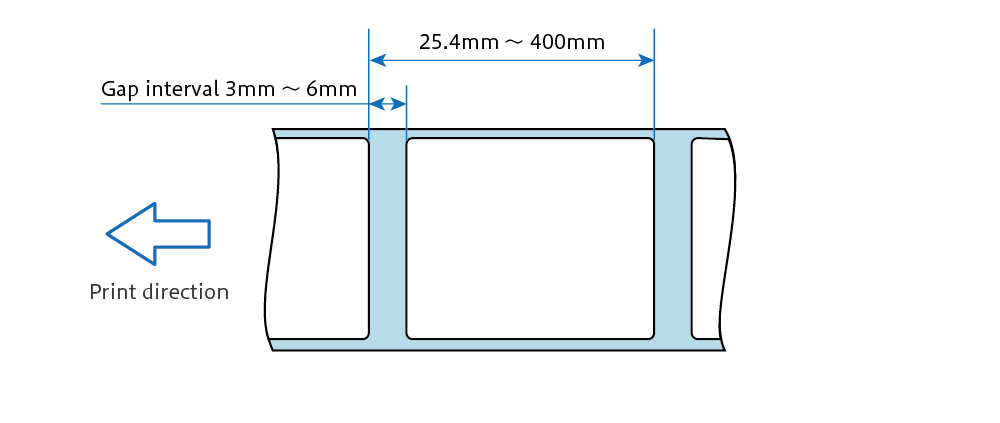

Available die cut label paper specifications

An example of using specially-shaped die cut label paper

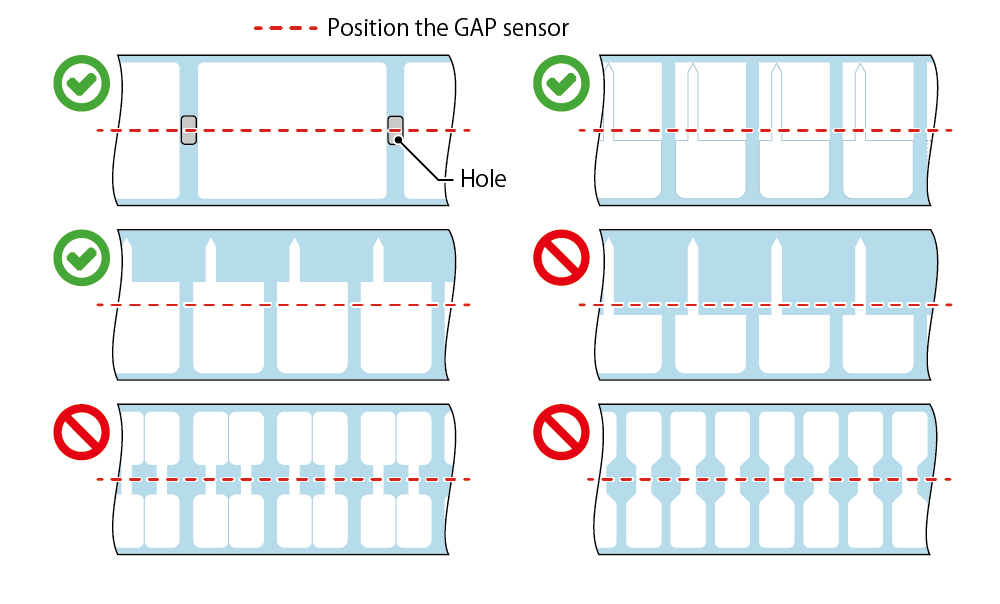

When using the GAP sensor

Use paper whose center meets the gap interval specifications for paper that passes the GAP sensor.

If paper with a gap in an area other than the cut position is used, it may not be cut at the correct position.

Part Names and Functions > Inside of main unit  GAP Sensor

GAP Sensor