Environmental Management

Environmental Charter

Environmental Philosophy

As a technical group with a core of information-related technology, compact precision machining, and assembly; Star positions environmental management activities as an important issue for the company and promotes business activities and fulfills social responsibilities to contribute to the realization of a society that is in harmony with the global environment.

Basic Environment Policies

- Among the environmental aspects related to the company's activities, products and services, the following items are the focus of environmental management.

Each division (each factory) prepares and implements an environmental policy that sets the theme for its activities.

Promote reducing waste and reusing and recycling activities.

Promote the efficient use of resources and energy conservation.

Reduce the use of harmful substances and properly manage chemicals.

Promote the development, manufacture, and service of environmentally friendly products.

Promote green purchasing.

Promote environment-communication internally and externally.

- Make improvements to the environmental management system and conduct pollution prevention activities.

- Comply with laws, regulations and regional agreements related to environmental aspects, as well as establish and undertake voluntary standards.

- Understand the company's environmental activities, the social environment, and the requests of stakeholders, and review the basic environmental policy.

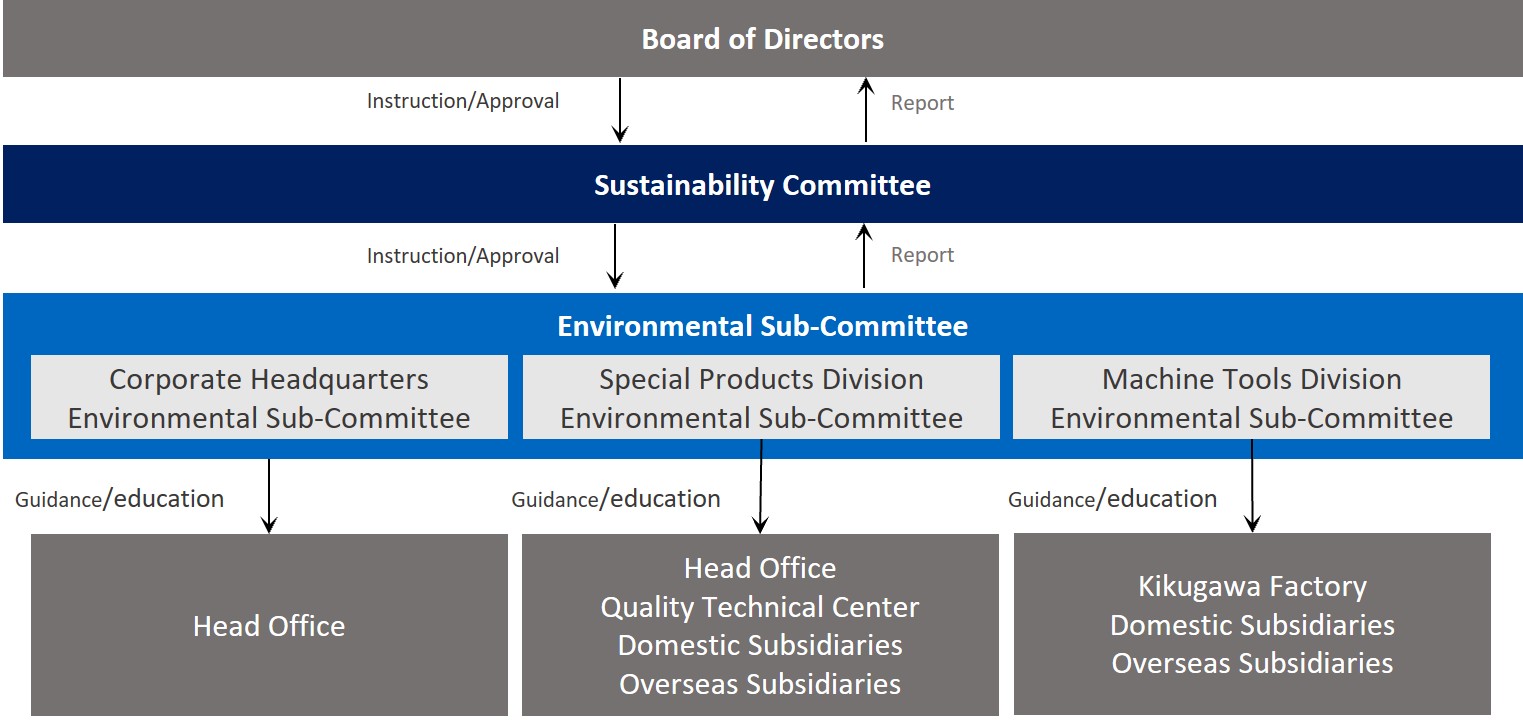

Environmental Management Promotion System

At the Group, the Sustainability Committee, which is a body to make decisions on important matters related to the environment, and chaired by the Representative Director, President and CEO, and comprised of full-time directors and executive officers, identifies material issues, sets goals for the resolution of these issues, and promotes Group-wide initiatives. The material issues and goals identified for the environment are disseminated to each unit responsible for the environment across the entire Group through the Environmental Sub-Committee of each division.

Environmental Action System

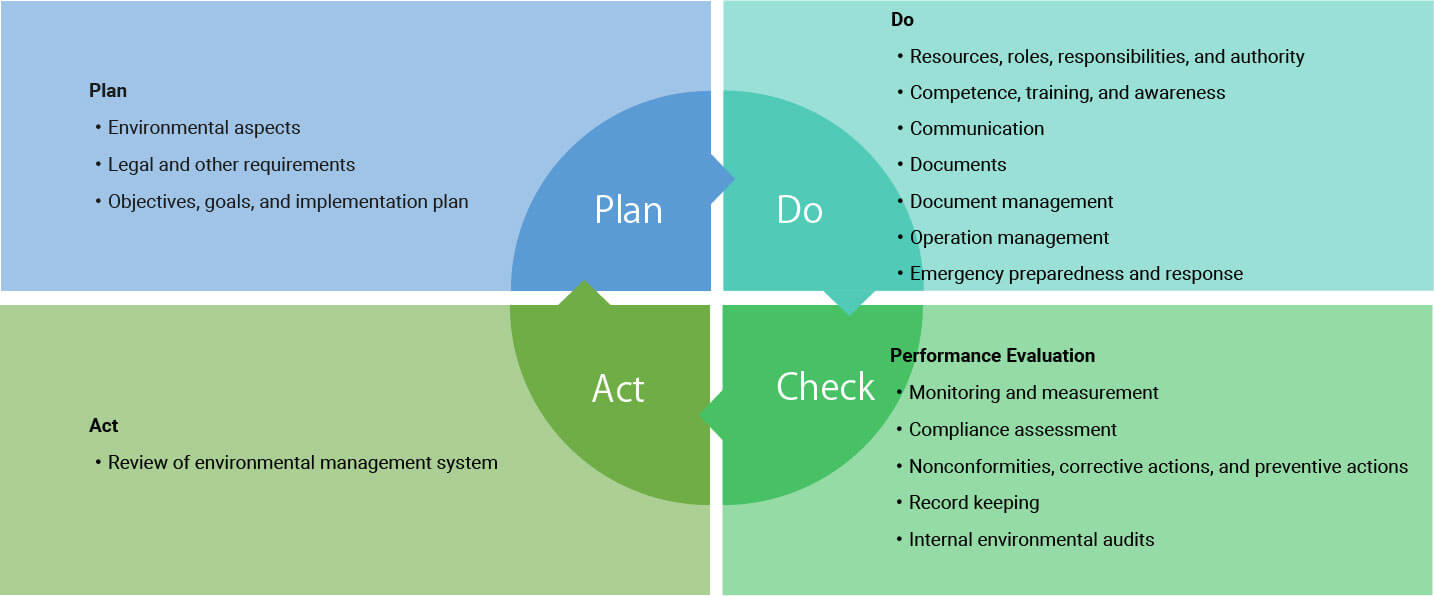

Correspondence to ISO14001

While promoting the acquisition of ISO14001 certification, we moved some of our sites to self-declaration. We will continue to promote environment-friendly business activities based on our environmental policy, including our affiliates sites that have shifted to a self-conformance declaration.

| Domestic | Company factories / Offices | Corporate Headquarters | Head Office | Acquired September 2001 (Self-conformance declaration: September 2010) |

|---|---|---|---|---|

| Special Products Division | Head Office/Quality Technical Center | Acquired March 2001 (Self-conformance declaration: September 2018) | ||

| Machine Tools Division | Kikugawa Factory | Acquired March 2002 | ||

| Subsidiaries | Star Metal Company Manufacturing Department | Kikugawa Factory | Acquired April 2006 | |

| Star Metal Company Sheet Metal Department | Acquired March 2007 | |||

| Micro Sapporo Company | Acquired March 2007 | |||

| Overseas | Subsidiary (Key production site) | Star Micronics Manufacturing Dalian Co., Ltd. (Dalian, China) | Acquired May 2002 | |

Environmental Audits

Internal Environmental Audits

Internal environmental audits are conducted regularly each year at domestic factories to confirm that environmental management systems are adequate and effective.

They also confirm that environmental management programs are appropriate and legally compliant.We also conduct skills enhancement seminars for internal environmental auditors to improve the expertise of people conducting internal audits.

A comprehensive environmental audit report is created listing items that fall below the expected standards, and the report is submitted to management as data for use in compiling the end-of-year environmental review. Thus, audits contribute to improvements in the following year.

External Environmental Audits

Domestic factories that have acquired ISO14001 certification are subject to environmental audits (environmental management system inspection) by an external inspection authority. Certification maintenance inspections take place once a year, while renewal inspections are conducted every three years.

The results of these inspections are submitted to management as data for use in compiling the end-of-year environmental review, thereby contributing to improvements in the following year.

Environmental Training

We believe that to maintain, and further improve, the level of our environmental activities, we need to change the mindset of every single employee.

Therefore, we offer training opportunities for all employees from new hires to management.

The training comprises four core categories: general, rank-based, leader-oriented and specialist.

Emergency Response

Every year, we plan and conduct emergency-related training of relevant parties and disaster prevention drills, as well as simulation-based drills for individuals and entire facilities based on manuals, which are evaluated as part of the process. These drills anticipate every conceivable accident or emergency (earthquake, typhoon, explosion, fire, blackout, chemicals leak, and airborne hazard, etc.).