SR-10J type C

With improved secondary machining capability and operability, the evolutionary advanced small diameter processing machine is now on market.

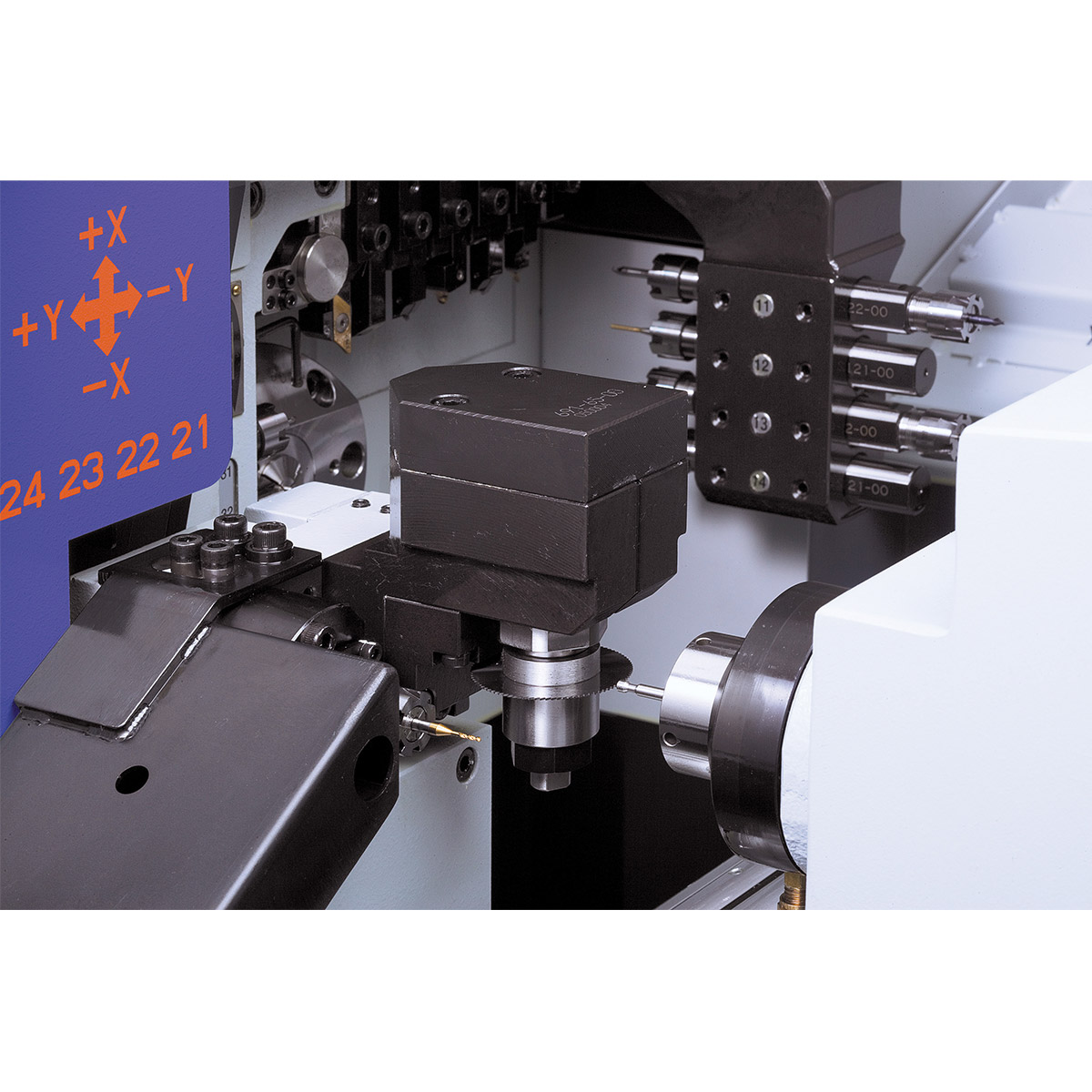

- A unique slanted dovetail slideway structure for insreased rigidity of the tool post.

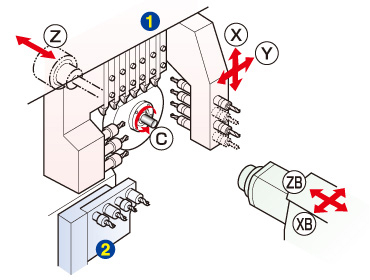

- Both the main spindle and sub spindle include the C-axis control function as standard.

- The manual pulse generator can be optionally set for setup operation.

Tool Post

| Tool Post | Tooling | ||

|---|---|---|---|

| ① |  |

Turning tool | 6 tools |

| Front-end working tool | 4 tools | ||

| Rear-end working tool | 4 tools | ||

| Power-driven tool | 3 tools | ||

| ② |  |

Rear-end working tool | 4 tools |

| Stationary tool | max. 8 tools | ||

| Power-driven tool | max. 6 tools | ||

Specifications

| Item | SR-10J type C | |

|---|---|---|

| Max.machining diameter | ø10mm(25/64in) | |

| Max.headstock stroke | Stationary G.B. | 135mm(5-5/16in) |

| Revolving G.B. | 105mm(4-9/64in) | |

| Number of turning tools | 6 tools(□8mm) | |

| 4-spindle sleeve holder | Number of tools | Front : 4 tools Rear : 4 tools |

| Max.drilling capability | ø6mm(15/64in) | |

| Max.tapping capability | M5×P0.8 | |

| Power-driven att. | Number of tools | 3 tools |

| Max.drilling capability | ø4mm(5/32in) | |

| Max.tapping capability | M3×P0.5 | |

| Spindle speed | max.10,000min-1 | |

| Drive motor | 0.5kw | |

| Rapid feed rate | 35m/min(X,Y,Z,ZB,XB) | |

| Main spindle indexing angle | C-axis control | |

| Main spindle speed | max.15,000min-1 | |

| Main spindle motor | 2.2kw(Continuous)/3.7kw(15min./60%ED) | |

| Dimensions (W×D×H) | 1,865×775×1,695mm | |

| Weight | 1,400kg | |

| Power consumption | 3.1KVA | |

Backworking Attachment

| Item | SR-10J type C | ||

|---|---|---|---|

| Max.chucking diameter | ø10mm(25/64in) | ||

| Max.length for front ejection | 70mm(2-3/4in) | ||

| Max.work projection length | 20mm(25/32in) | ||

| 4-spindle backworking unit | Number of tools | 4 tools | |

| Max.drilling capability | Stationary tool | ø4mm(5/32in) | |

| Power-driven att. | ø4mm(5/32in) | ||

| Max.tapping capability | Stationary tool | M3×P0.5 | |

| Power-driven att. | M3×P0.5 | ||

| Sub spindle indexing angle | C-axis control | ||

| Sub spindle speed | max.10,000min-1 | ||

| Sub spindle motor | 0.55kw(Continuous)/1.1kw(15min./50%ED) | ||